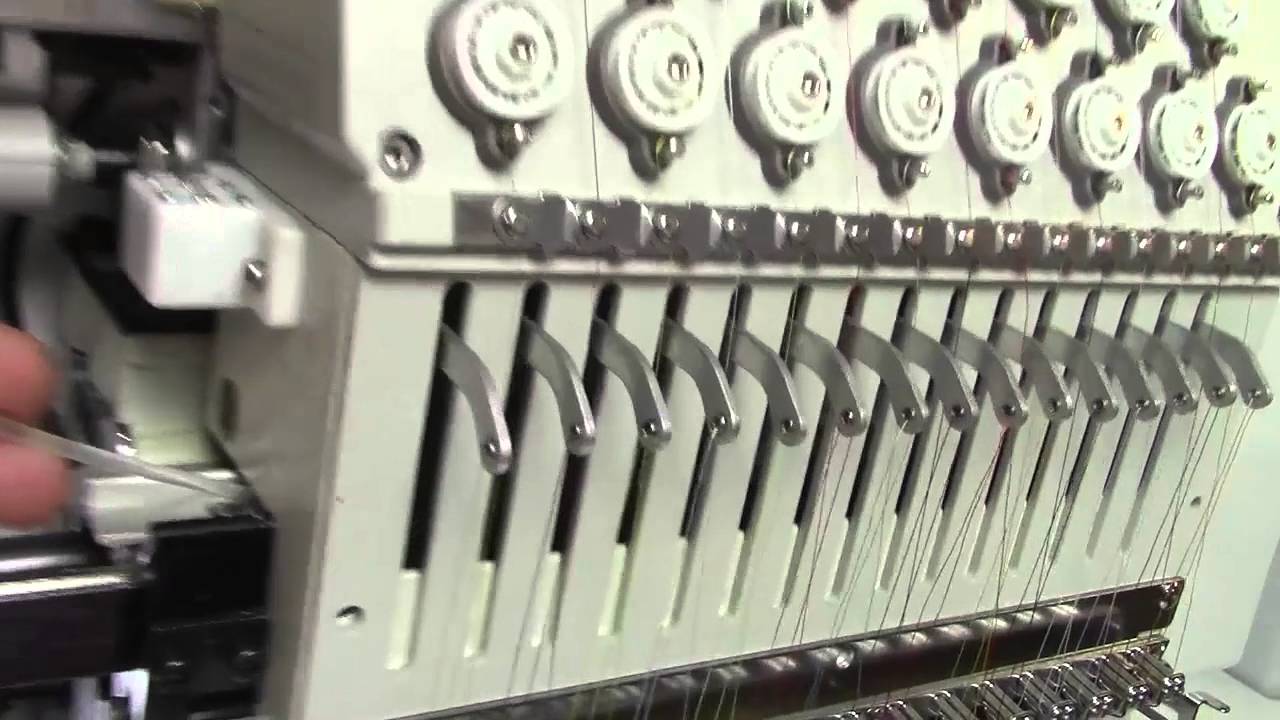

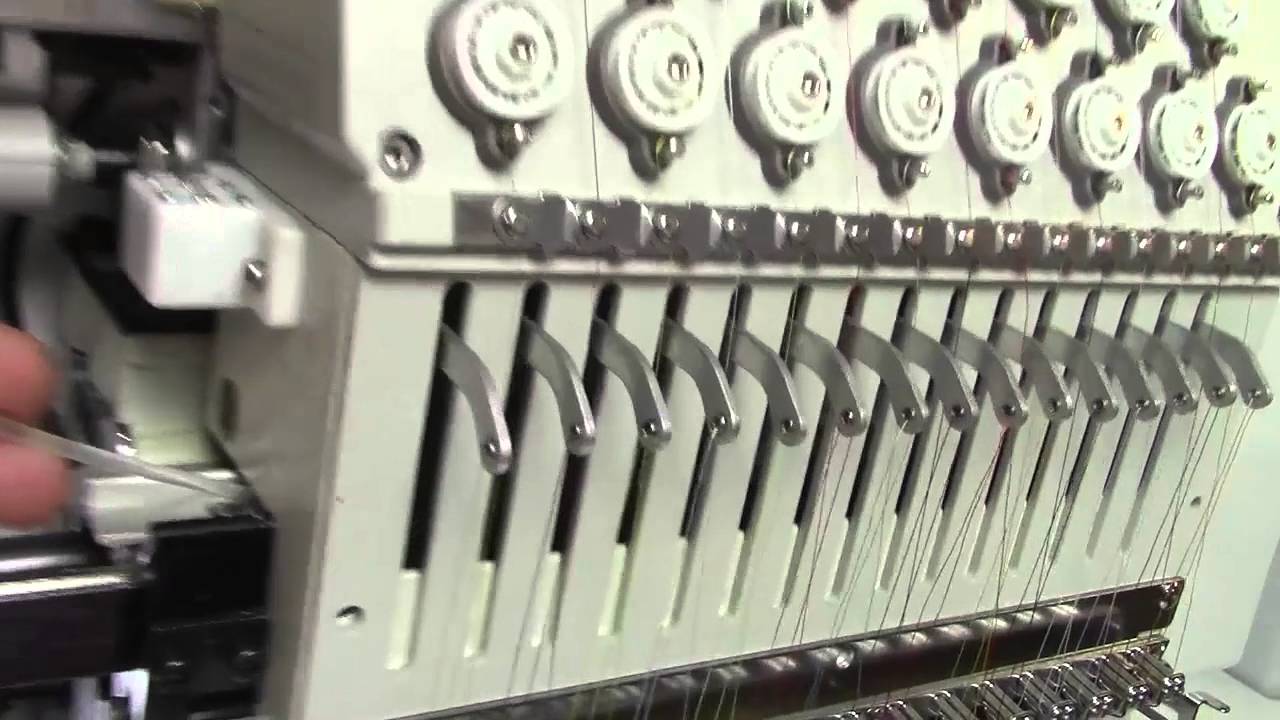

Make sure both top and bottom tensions are about the same. Make sure to thread your embroidery machine through the tension bars properly.

Troubleshooting On Screen Troubleshooting Brother International Entrepreneur Pro Pr1000e Operation Manual Page 2 Brother Dream Machine Entrepreneur Brother

The 3 most common errors you may encounter starting up your commercial embroidery machine and how to fix them1.

. Dont be afraid to adjust your tension with embroidery the same way you would with sewing. Remove the bobbin case. USB Port - Convenient design load.

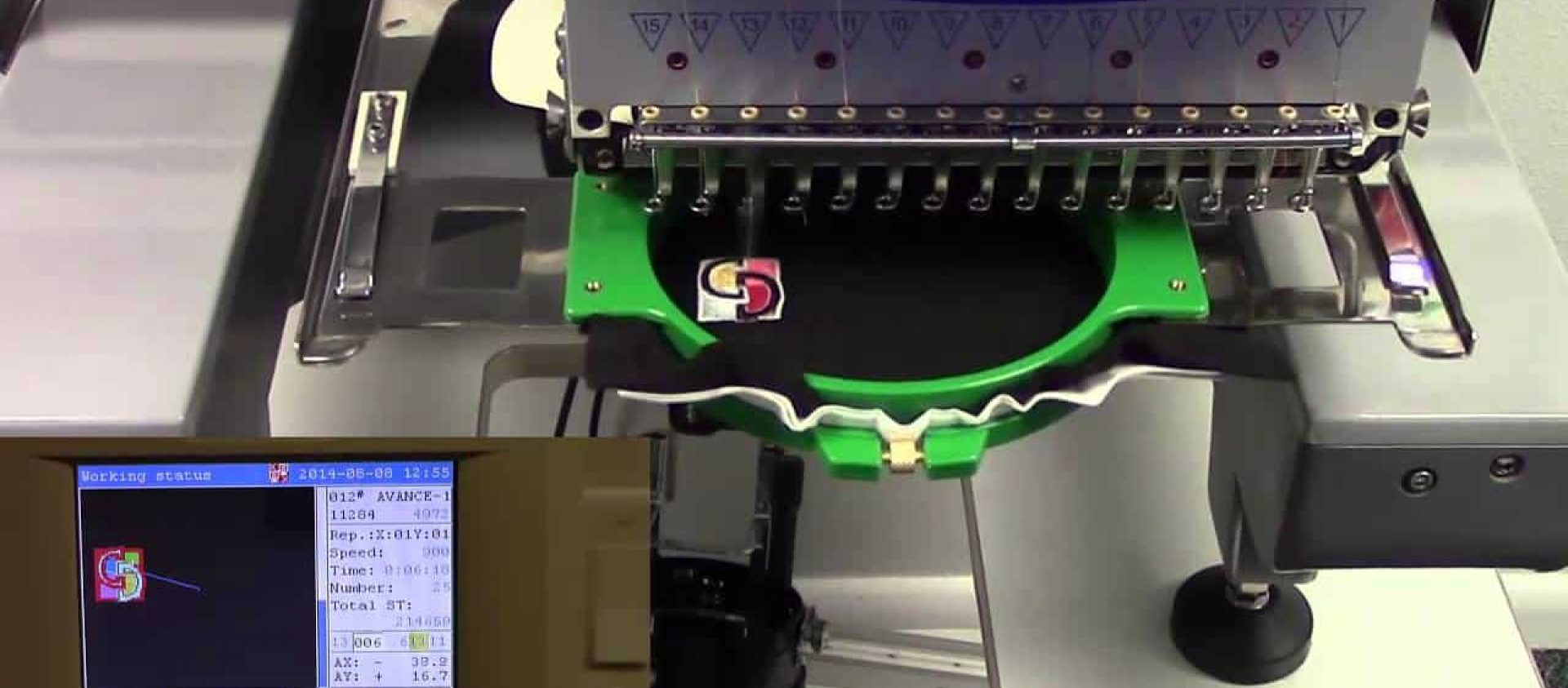

Power the machine on and allow it to continue to the main drive screen. DST USB flash card. Your top thread tension might be too loose.

The bobbin is not inserted or not inserted properly. Use the Troubleshooter below. Clean the machine every 3 to 4 hours of stitching time.

If user selects the machine will stay at Embroidery Cancel Status. At this time the machine will not work even when user presses the start key. In this case you want to see if your top tension is too loose or bobbin is too tight.

Remove the needle plate and bobbin case. Limitations Embroidery Areas. The basic troubleshooting for these problems is to insert a new needle.

Oil the machine. 300 x 300 mm wide maximum size. Remove all fuzz and check for tiny bits of thread that might be stuck in the bobbin case.

To check whether the problem really is in tension remove your hoop and inspect the reverse side of your embroidery. This is especially crucial because the high speed of the embroidery creates more lint and fuzz than you encounter during normal sewing. HUGE design memory on board - 800 designs or 100 million stitches.

Too loose on one and too tight on the other will cause problems. Re-thread both top bobbin thread. Answer yes or no questions and follow video instructions to the most common issues.

Make sure the thread is free of both the bobbin and hook area. Knowledge base All about embroidery formats. Was this article helpful.

Check for loose tension. Select needle six 6. Confirm and turn cancel embroidery to confirm embroidery which indicates the machine has entered Embroidery Ready Status.

Garment Puckering If you shirt looks great before you remove it from the hoop but puckers after you take it out of the. Embroidery problem solving tips for needle breaks skipped stitches top embroidery thread shows on bottom and more problems. Looping on the top of your embroidery is typically caused by tension issues.

Do this by loosening each of the two 2 flathead screws with an offset screwdriver provided in the machines toolkit 3. Remove the needle plate and bobbin case. 28 on board fonts for easy monogramming and lettering projects.

A hint window will display on the screen for user to. Here are some suggestions for helping solve machine. Full color touch screen control panel - makes it so simple to use.

The problem is common for machine embroidery. Apply two drops of oil every 3 to. If the Troubleshooting steps didnt help ColDesi has an advanced tech support ticketing system we use to make sure everyone gets the help they need as quickly as possible.

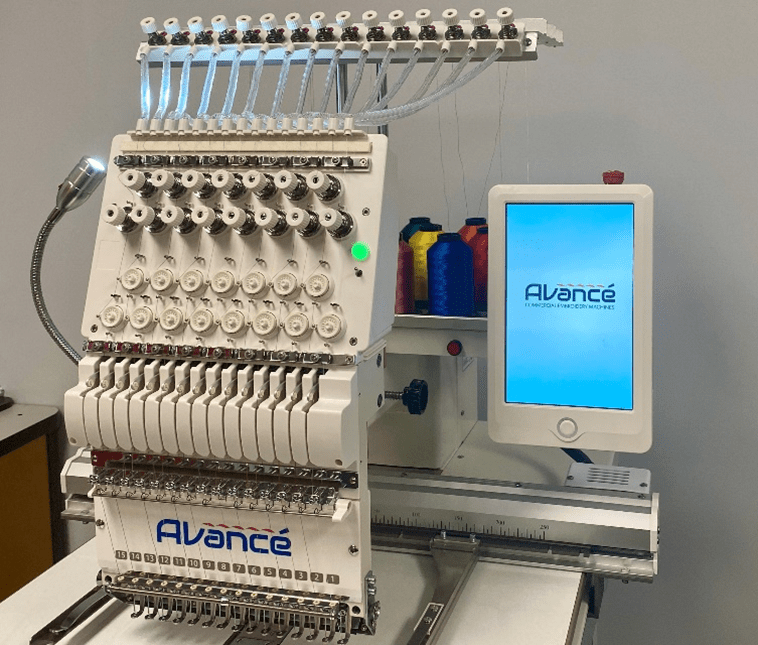

59 out 129 found this helpful. It is prevailing to have needle breaks. Recording of a Live Webinar on setting and troubleshooting tensions in the Avance commercial embroidery machine series from ColDesiFebruary 2016.

Your machine may be not threaded correctly. Select needle seven 7Do this using the keys on the control panel 3. Do this using the keys on the control panel 3.

Power the machine on and allow it to continue to the main drive screen. Do this by loosening each of the two 2 flathead screws with an offset screwdriver provided in the machine s toolkit Timing for HCS-1201. Check your needle and your tension.

Basic Machine Embroidery Troubleshooting Help Use The Correct Needles Be sure to select the correct needle for your machine home machines use flat shank needles and. 101 Full color high resolution touch screen interface. Your needle may be damaged or just secured not well enough.

As the name suggests needle breaks occur if the needle is bent loose small or if the stitch position is not matching the surface.

Setting And Troubleshooting Tensions On The Avance 1501c Youtube

Coldesi Inc Announces The Release Of All New Avance Commercial Embroidery Machine News

Mesin Bordir Kepala Tunggal Produsen Dan Pemasok Pabrik Cina Teknologi Wanyang

Avance Multihead Maintenance How To Set Needle Depth Youtube

4 Tips For Bigger Embroidery Business Profits

![]()

No Needle Error Avance Troubleshooter On Vimeo

Avance Single Head Embroidery Support

Avance Single Head Embroidery Support

How To Make Embroidered Patches Youtube Machine Embroidery Tutorials Embroidered Patches Patches

Avance 1501c Multi Head Embroidery Machine Options Avance Commercial Embroidery Machines

Troubleshooting On Screen Troubleshooting Brother International Entrepreneur Pro Pr1000e Operation Manual Page 2 Brother Dream Machine Entrepreneur Brother

Avance Training Resolving Common Errors Common Start Up Errors Youtube

How To Set Tension Avance 1501c Professional Embroidery Machine Training Youtube

Avance 1501c Multi Head Embroidery Machine Options Avance Commercial Embroidery Machines

Avance Single Head Embroidery Support

Avance Single Head Embroidery Support

Avance Multihead Embroidery Machine Maintenance Youtube

Avance Embroidery Machine Archives Coldesi

Avance 1501c Multi Head Embroidery Machine Options Avance Commercial Embroidery Machines